In today's world, it is particularly important to conserve resources and make production processes as efficient as possible, especially in the plastics. A team of SRH students analyze different anomaly detection algorithms in plastic industry.

What is the project about?

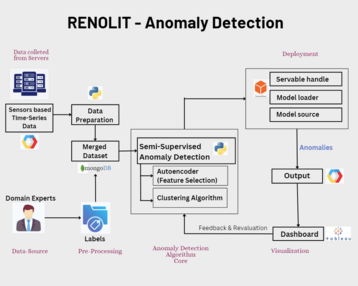

In today's world, it is particularly important to conserve resources and make production processes as efficient as possible, especially in the plastics industry. Machine learning models are becoming increasingly important for evaluating real-time process information in order to be able to intervene if critical events occur. However, currently the reactions to such events are based on the know-how of each machine operator and there is no system in place to detect anomalies within the data and give suitable suggestions on what the issue might be.

This can lead to a production line running and producing non-sellable goods. Not only is the raw material wasted, but also huge amounts of electricity and gas are lavished, and the scrap amounts need energy input again to be recycled, if possible. This leads to the business case of a machine learning model, which evaluates real time machine data to be able to give machine operators a statement as to whether the film they are currently producing is good material or whether quality parameters are outside the tolerances. The goal is to suggest adjustment parameters to bring the film back within the tolerances by investigating the main influencing variables of the process control on various quality characteristics.

Prof. Dr. Swati Chandna, Prof. Dr. Binh Vu, students of the April 2022 batch